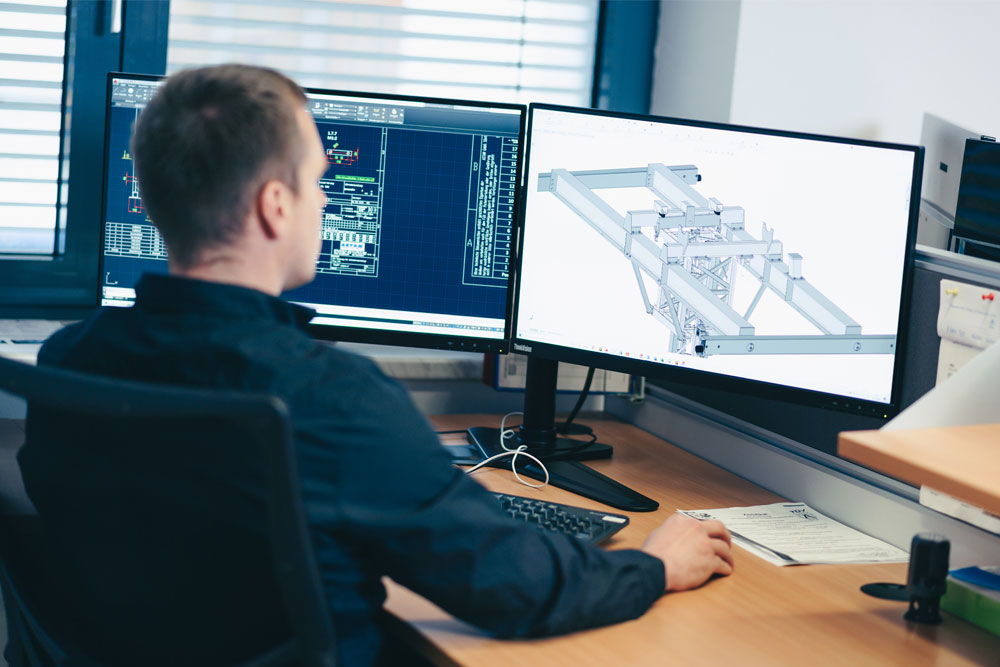

Engineering

We leave no planning needs unfulfilled.

Your contact person

Ing. Mario Ferk

- Quality management

- Welding supervisor IWE

- Engineering

Planning options

The range of possible planning tools extends from 2D design plans to the creation of true-to-scale prototypes. Take a look at the options offered by our design office:

Facts and figures

0

Y

Experience

0

E

Employees

0

Tsd m²

Production area

We have strong partners for your project